Tire valve testing technology provides driving safety protection

Tire valve testing technology provides driving safety protection

With the continuous development of the automotive industry, driving safety has become more important. With the continuous increase in the number of cars in use, the R&D department of Shengshi Weiye has also placed greater emphasis on the quality of valve valves. Today, we will conduct a new round of testing on the tire valve.

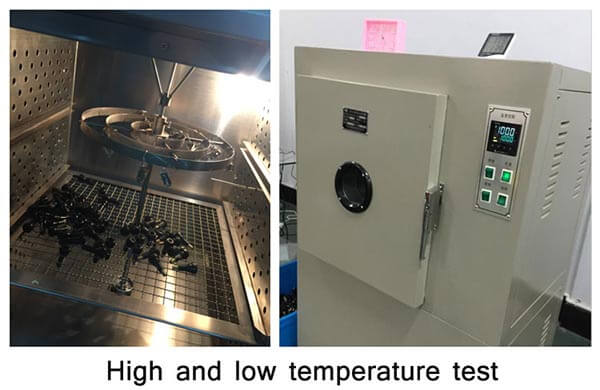

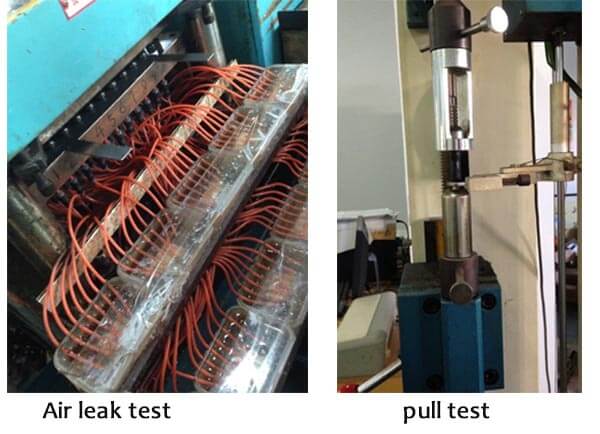

This round of testing mainly focuses on the sealing, high and low temperature, and tensile strength of the valve.

Testing products/quantity

TR414/200 pieces

TR413/200 pieces

TR415/200 pieces

Test results: Qualified

In order to produce high-quality valves, we conduct rubber tensile tests on the valves every day.

Air tightness testing is also a test that needs to be done during the production process. Our valves are all tested for 100% air leakage.

The hardness test of rubber must be conducted before each batch of rubber production

Only by continuously upgrading the testing technology of tire valves and the quality management of manufacturers, can we believe that the safety of tire valves will be further guaranteed, safeguarding driving safety. I hope that more innovative technologies and policies will be introduced in the future, so that every driver can travel safely on the road.